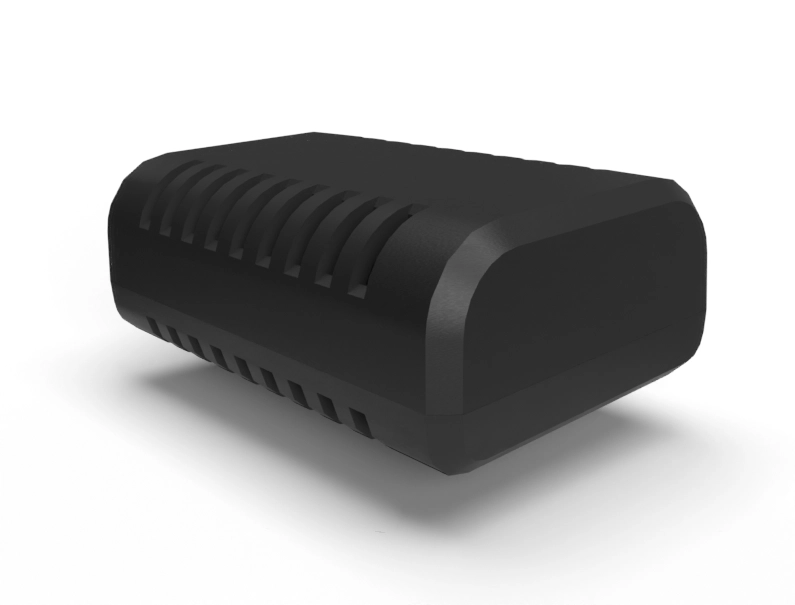

Established in 2004, New Age Enclosures was founded with three clear objectives. First, to develop a cutting-edge line of off-the-shelf electronic enclosures tailored for today's compact electronics, setting a standard for well-designed indoor and outdoor stocked enclosures. Our designs, akin to Apple's impact on the computer industry, shape and encase the future of electronic solutions.

Established in 2004, New Age Enclosures was founded with three clear objectives. First, to develop a cutting-edge line of off-the-shelf electronic enclosures tailored for today's compact electronics, setting a standard for well-designed indoor and outdoor stocked enclosures. Our designs, akin to Apple's impact on the computer industry, shape and encase the future of electronic solutions.

Secondly, we provide comprehensive in-house services, empowering our customers to seamlessly transition from Off-The-Shelf to Market-Ready Enclosures™. As a single-source solution, New Age significantly streamlines the process, saving our customers both money and valuable development time. Our customization services encompass CNC Cutouts, Part Decorating, Custom Colors and Resins, RF/EMI Shielding, Custom Tooling & Tooling Insets, and fully customized enclosure design and fabrication.

Our third goal revolves around cultivating long-term partnerships with customers, grounded in open communication and reliable performance. Despite serving thousands of customers worldwide, our commitment to each one remains unwavering. Being an employee-owned corporation elevates our dedication to a higher level.

All New Age enclosures are molded and customized at our corporate facility in California, showcasing complete in-house capabilities including a tool room, molding operations, machining center, and part decorating facilities. This comprehensive process control ensures end-to-end product quality control, offering a seamless transition from Off-The-Shelf to Market-Ready Enclosures™.

New Age Enclosures, a division of Alltec Integrated Manufacturing, Inc., follows the same AS9100 aerospace standard as its parent corporation, a leader in custom injection molding for the aerospace industry. ISO quality registered, we consistently meet the demanding aerospace standard, embedding this high-quality commitment into every injection-molded electronic enclosure. Our proven track record of quality sets us apart, and we look forward to delivering exceptional solutions for you.