Choosing the Right Electronic Enclosure Manufacturer for Your Electronic Devices: 7 Essential Considerations

Sourcing the ideal enclosure for today's compact electronics can be a complex challenge. To ensure optimal performance, you must carefully consider several key factors:

- Functionality: Verifying your device will operate efficiently within the enclosure's constraints.

- Fit: Guaranteeing sufficient interior space to accommodate all necessary components.

- Durability: Selecting an enclosure that can withstand the intended environmental conditions.

- Aesthetics: Prioritizing an enclosure design that not only serves its purpose but also presents an attractive, polished appearance.

Balancing these essential criteria is crucial when sourcing the perfect enclosure solution for your modern electronic device. In this article, we'll discuss seven ways to overcome these challenges.

1. Establish a Comprehensive Design Brief

Before engaging with an off-the-shelf (OTS) enclosure provider, it's crucial to have a thorough understanding of your project's requirements. This includes details on the device's functionality, dimensions, environmental factors, and any regulatory standards that must be met. Clearly communicating these specifics to the representative will enable them to better assist you in selecting the right enclosure solution.

If your project involves sensitive information or trade secrets, do not hesitate to request a non-disclosure agreement (NDA) from the manufacturer. This will ensure the protection of your intellectual property. If the OTS enclosure provider is unwilling to sign an NDA, that may be a sign to look elsewhere for your sourcing needs.

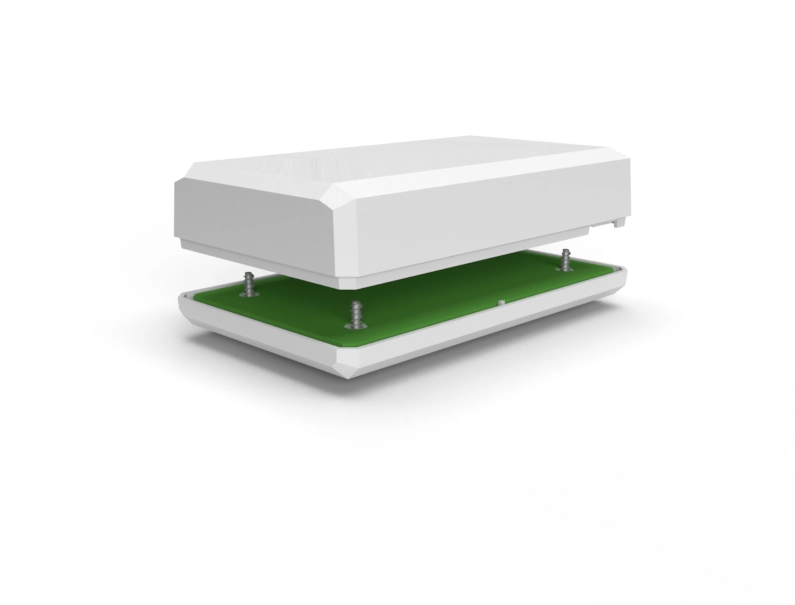

2. Request a 3D Model of the Target Enclosures

Requesting a 3D model of the target enclosures is a crucial step in the selection process. By obtaining a 3D model, you can leverage your CAD software to visualize and analyze the enclosures' ability to accommodate your PCB before committing to a purchase. Many CAD programs today allow you to evaluate factors such as airflow, thermal management, and structural integrity within the enclosure. If the OTS enclosure provider is unwilling to provide you with a 3D model, that may be a red flag. Their responsiveness and willingness to share technical details can be a strong indicator of the level of service and support you can expect throughout the project.

3. Determine Component Placement and Layout

Space optimization is critical when working with compact electronic enclosures. Taking the time to order physical samples and test your prototype components within them can yield invaluable insights. By physically placing your board and parts inside the enclosure, you can conduct real-world evaluations on factors like heat generation, signal interference, and accessibility of connectors and ports. This hands-on approach allows you to fine-tune the component layout for optimal performance and functionality. If the OEM is unwilling to provide samples, you may be able to source them through distributors. This flexibility allows you to thoroughly vet the enclosure before a larger purchase, ensuring a perfect fit and seamless integration.

4. Communicate Upgrades and Modifications

Feature customization and modifications are often necessary to meet your specific use case and extend the lifespan of your product. These may include changes to the material type, such as upgrading from standard ABS plastic to a more durable polycarbonate or adding specialized venting. Be sure to inquire with the enclosure manufacturer about their ability to produce the enclosure in alternate materials, colors, or with CNC modifications at their facility. If the OTS enclosure provider is unable to accommodate these customizations, it may be a sign that they are not the right source for your project's needs.

5. Explore Available Materials

When evaluating plastic electronic enclosure manufacturers, it's crucial to prioritize those that offer a diverse selection of lightweight yet durable materials. The ideal materials should provide excellent structural integrity, impact resistance, and versatility, while keeping weight and production costs low. Take the time to thoroughly understand the specific material options each manufacturer can provide, as this will ensure you select the enclosure solution that delivers optimal product quality and performance.

6. Research Assembly and Serviceability

When choosing a manufacturer, prioritize enclosures designed with ease of access and serviceability in mind. Look for features that simplify the assembly and maintenance processes, such as snap-fit components and tool-less assembly. These elements streamline both installation and servicing, making the product more user-friendly and cost-effective to maintain over its lifespan.

7. Establish Aesthetic and Branding Elements

While prioritizing functionality is crucial, the aesthetic and branding elements of small electronics enclosures should not be overlooked. A reputable manufacturer will incorporate design features that not only enhance the product's visual appeal but also reinforce your brand identity, making your device stand out in the crowded market. This includes sleek contours, ergonomic shapes, and customizable branding options such as part marking and custom-colored materials. By thoughtfully balancing form and function, you can create an enclosure that not only performs exceptionally but also reflects the quality and professionalism of your brand.

In Summary

Designing compact electronic enclosures requires striking the perfect balance between functionality, efficiency, and aesthetics. At New Age Enclosures, we excel in this area by adhering to these core design principles and leveraging cutting-edge tools and high-quality materials. Our innovative and reliable enclosures are meticulously crafted to meet the ever-evolving needs of modern electronic devices.

When you choose New Age Enclosures as your manufacturing partner, you can expect unparalleled quality, performance, and design excellence. Our comprehensive enclosure solutions are designed to seamlessly integrate with your product vision and elevate your brand's presence in the market.

Contact our team today to discuss how we can help bring your product to life through our expertly engineered enclosure designs. With our unwavering commitment to innovation and customer satisfaction, we are confident in our ability to deliver a tailored solution that exceeds your expectations.

Are you in the aerospace industry? Check out ARM!